Hi-Acts Academy: Residual stress measurement for optimizing industrial components – From Science to Application

Zoom Online

For manufacturers and product developers striving to extend lifetime, improve performance, and enhance reliability of their products, understanding residual stress is key. In this webinar, we’ll show how the Swedish company Scatterin partners with DESY to help their customers translate scientific insights into real production advantages — improving quality, safety, and innovation speed.

Residual stresses have a decisive impact on component and material performance, especially in demanding applications. Synchrotron X-ray diffraction (S-XRD) is a powerful, non-destructive method that enables high-resolution measurements deep inside components. These insights are not only valuable for science but also critically important for industry, as they influence the lifetime, safety, and overall performance of many parts and products.

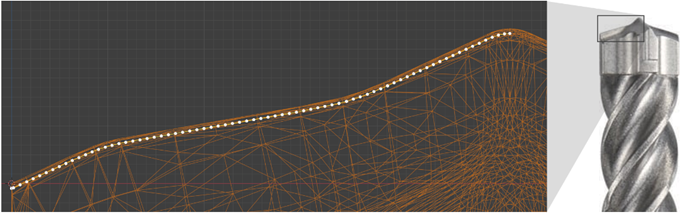

Example residual strain/stress measurement points on drill bits. (source: Scatterin)

One of the main barriers for companies in using the enormous potential of synchrotron X-ray sources is the lack of in-house expertise for such measurements, as well as the complexity of analyzing and interpreting the resulting data. Scatterin, a long-standing partner of research institutions like DESY and Hereon, offers an end-to-end service for material, process, and component analysis at synchrotron X-ray facilities.

In this session, Dr. Malte Blankenburg (Beamline Scientist at DESY & Synchrotron Expert at Scatterin) and Dr. Ahmet Bahadır Yıldız (CEO and Co-Founder of Scatterin) will provide an in-depth look at how Scatterin collaborates with DESY. After a concise introduction to the S-XRD measurement method at DESY, they will present real-world examples showing how industry customers use these services to enhance materials and product performance.

Dr. Ahmet Bahadır Yıldız (CEO and Co-Founder of Scatterin)

Dr. Malte Blankenburg (Beamline Scientist at DESY & Synchrotron Expert at Scatterin)

The webinar will be moderated by Johannes Blum, Innovation Manager at DESY and representative of Hi-Acts, an innovation platform connecting industry, medicine, and research in the field of accelerator-based technologies.